The  Dielectric Breakdown Sensor Definition determines when electric fields are sampled during timestepping. At each time sample, cell edges are evaluated for potential dielectric breakdown resulting from an electric field strength that exceeds the dielectric strength of its material. The electric field values at each cell edge are written to a file on disk for visualization. The accompanying dielectric breakdown sensor specifies which cell edges to evaluate.

Dielectric Breakdown Sensor Definition determines when electric fields are sampled during timestepping. At each time sample, cell edges are evaluated for potential dielectric breakdown resulting from an electric field strength that exceeds the dielectric strength of its material. The electric field values at each cell edge are written to a file on disk for visualization. The accompanying dielectric breakdown sensor specifies which cell edges to evaluate.

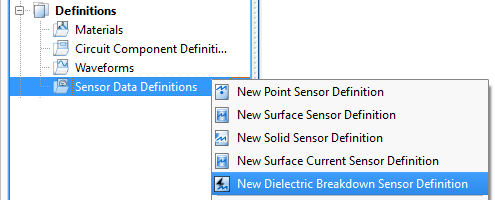

Users can access the Dielectric Breakdown Sensor Definition Editor by either right-clicking on the Definitions branch of the Project Tree and selecting New Dielectric Breakdown Sensor Definition, or double-clicking on an existing definition in the Project Tree.

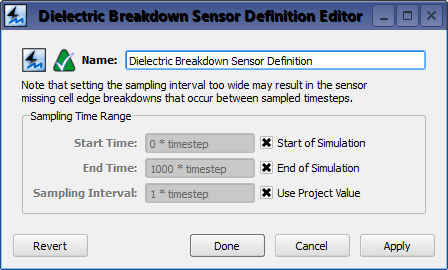

The Sampling Time Range settings specify when cell edge data is checked for breakdown and saved to disk for visualization. Users can either enter the desired Start Time and End Time, or check Start of Simulation and End of Simulation to assign the sampling time range to the simulation's beginning and ending values, respectively. Users can either enter a value for the Sampling Interval, which determines how often data is sampled within the time range, or check the Use Project Value option to define the Sampling Interval using the value in the advanced tab of the project properties editor.

Four buttons provide options for completing changes to the project properties:

- Revert: discards changes and restores the previously saved settings.

- Done: closes the window and saves the entered specifications, which are visible when the window is re-opened.

- Cancel: closes the window and does not save the entered specifications.

- Apply: saves the entered specifications but does not close the window.

![]() Dielectric Breakdown Sensor Definition determines when electric fields are sampled during timestepping. At each time sample, cell edges are evaluated for potential dielectric breakdown resulting from an electric field strength that exceeds the dielectric strength of its material. The electric field values at each cell edge are written to a file on disk for visualization. The accompanying dielectric breakdown sensor specifies which cell edges to evaluate.

Dielectric Breakdown Sensor Definition determines when electric fields are sampled during timestepping. At each time sample, cell edges are evaluated for potential dielectric breakdown resulting from an electric field strength that exceeds the dielectric strength of its material. The electric field values at each cell edge are written to a file on disk for visualization. The accompanying dielectric breakdown sensor specifies which cell edges to evaluate.