Electrostatic discharge (ESD) analysis determines an electronic device's susceptibility to damage and failure from the current generated by an ESD event.

This analysis utilizes multiple aspects of an XFdtd project:

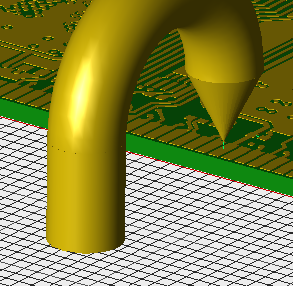

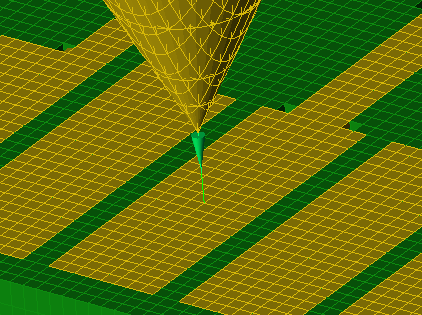

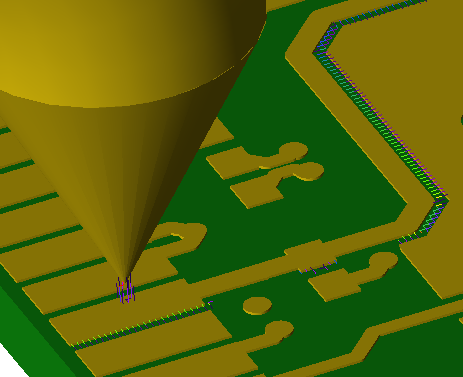

- Geometry: a device under test (DUT) is added to the project by importing a printed circuit board (PCB) or CAD model, or created using XF's modeling operations. A conducting ESD gun is also added and then grounded to a PEC outer boundary condition.

- Materials: dielectric strength must be defined for each material.

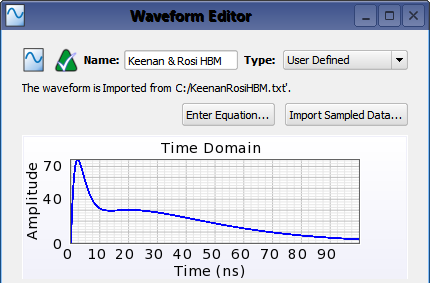

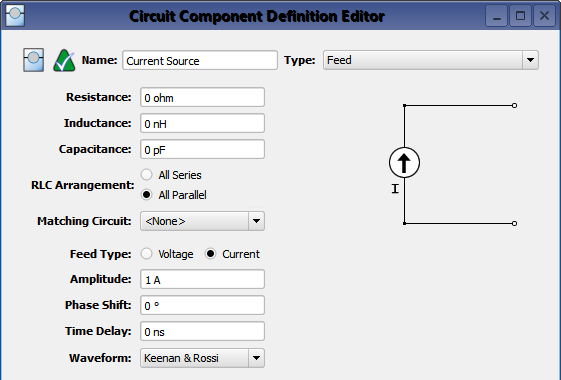

- Excitation: a user-defined waveform definition models the time-domain shape and strength of the discharged signal. The signal is injected into the simulation space through a current source.

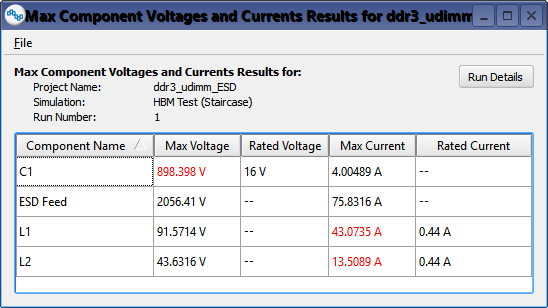

- Circuit components: rated voltage and current values must be defined for each circuit component.

- Grid: gridding properties are set to resolve geometry features with sufficient accuracy.

- Sensors: dielectric breakdown sensors monitor cell edges for electric fields that exceed input parameters and identify locations where damage is likely.

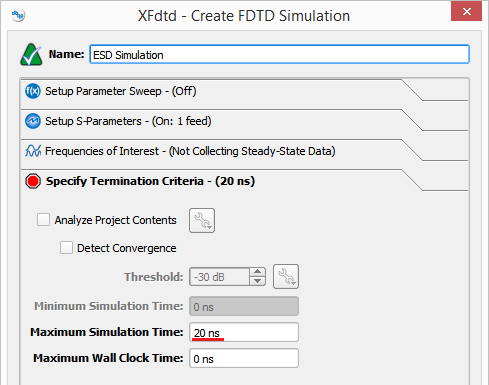

- Simulation: S-parameters and steady-state data are disabled and settings are adjusted to ensure simulation time is sufficient to resolve the waveform.

- Results: areas of potential dielectric breakdown and circuit components susceptible to damage are reported and available for analysis through the results browser.

Geometry

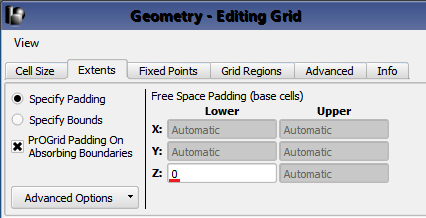

A fully detailed DUT model is added to an XF project using the PCB and CAD import capability. In a lab, the DUT is often placed on a flat, grounded surface while the tests are performed. This setup is achieved in XF by using the PEC boundary condition and then manually adjusting the free space padding to zero cells in the desired direction.

Materials

Each material definition, such as an electric nondispersive material, includes a dielectric strength value that sets the maximum electric field it can withstand without experiencing dielectric breakdown, or losing its insulating properties. Checking every cell edge in the simulation space at each timestep negatively impacts simulation speed. As such, a dielectric breakdown sensor must also be created to reduce the volume that must be monitored.

Excitation

ESD testing procedures and models are defined by numerous standards from organizations including, but not limited to, the American National Standards Institute (ANSI), JEDEC, and the International Electrotechnical Commission (IEC).

The table below provides examples of ESD standards and waveforms.

| ESD Standards Document | ESD Waveform |

|---|---|

| MIL-STD-883K | Human Body Model (HBM) |

| ANSI/ESDA/JEDEC JS-001-2017 | Human Body Model (HBM) |

| ANSI/ESDA/JEDEC JS-002-2014 | Charged Device Model (CDM) |

| ANSI/ESD STM5.2-2012 | Machine Model (MM) |

| ANSI/ESD SP5.3.2-2013 | Socketed Device Model (SDM) |

| ANSI/ESD STM5.5.1-2016 | Transmission Line Pulse (TLP) |

| ANSI/ESD SP5.6-2009 | Human Metal Model (HMM) |

| ESD TR5.4-01-00 | Transient Inducted Latch-Up (TLU) |

| ESD TR25.0-01-16 | Charged Board Event (CBE) |

Circuit Components

It is more common for circuit components to suffer damage from overvoltages and overcurrents during ESD testing than it is for dielectric breakdown to occur, so XF monitors for electronic component failures during ESD testing. Rated voltage and current input parameters, which are obtained from electronic component data sheets, can be added to all circuit component defintion types, such as a passive load. This functionality flags each component that exceeds its rated design parameters and reports to users their susceptibility to permanent damage.

Grid

Sensors

Defining the dielectric strength of a material enables users to monitor FDTD cell edges for potential dielectric breakdown during transient simulations using a dielectric breakdown near-field sensor.

This sensor instructs the calculation engine to monitor cell edges for electric fields that exceed the dielectric strength of their constituent material and record instances at which dielectric breakdown is likely to occur. This sensor requires users to define the free space dielectric strength that will be used for all edges without an assigned material. The default free space dielectric strength value is 3.0 MV/m, which is approximately the dielectric strength of air at sea level. The sensor also allows users to define a bounding box in order to limit the volume that is monitored for dielectric breakdown. Users can therefore obtain computational savings by defining specific areas of interest as opposed to examining the entire computational space. Materials with infinite dielectric strength are ignored by the dielectric breakdown sensor.

Simulation Setup

Results

References

- Cerri, G., R. Leo, and V. M. Primiani, "ESD indirect coupling modelling," IEEE Trans. On EMC, 38, pp. 274 - 281, 1996.

- Keenan, R. K., and L. K. A. Rossi, "Some fundamental aspects of ESD testing," Proc. of IEEE Int. Symp. on Electromagnetic Compatibility, pp. 236 - 241, 1991.

- Songlin, S., B. Zengjun, T. Minghong, and L. Shange, "A new analytical expression of current waveform in standard IEC61000-4-2," High Power Laser and Particle Beams, 5, pp. 258 - 271, 2003.

- Yuan, Z., T. Li, J. He, S. Chen, and R. Zeng, "New mathematical descriptions of ESD current waveform based on the polynomial of pulse function," IEEE Trans. on EMC, 48(3), pp. 589 - 591, 2006.

- Wang, K., D. Pommerenke, R. Chundru, T. Van Doren, J. L. Drewniak, and A. Shashindranath, "Numerical modeling of electrostatic discharge generators," IEEE Trans. on EMC, 45(2), pp. 258 - 271, 2003.

- Wang, K., J. Wang, and X. Wang, "Four order electrostatic discharge circuit model and its simulation," TELKOMNIAK, 10(8), pp. 2006 - 2012, 2012.

- Berghe, S. V., and D. Zutter, "Study of ESD signal entry through coaxial cable shields," J. Electrostat., 44, pp. 135 - 148, 1998.

- Lundengard, K., M. Rancic, V. Javor, and S. Silvestrov, "Electrostatic discharge current modelling using multi-peaked analytically extended function," Proc. of 2nd International Multidisciplinary Conference on Computer and Energy Science (SpliTech), pp. 272 - 277, 2017.