XF's gridding algorithm determines how the 3-D CAD geometry and surrounding simulation space is discretized into Yee cells. The algorithm allows users to utilize PrOGrid Project Optimized Gridding®, specify the grid manually, or use a combination of both.

Gridding settings are available for the main grid, as well as each part, circuit component, modal waveguide, and nodal waveguide.

Background

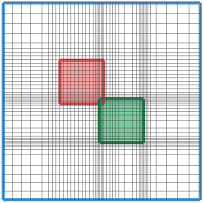

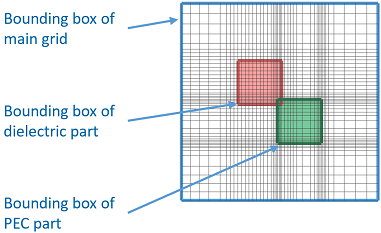

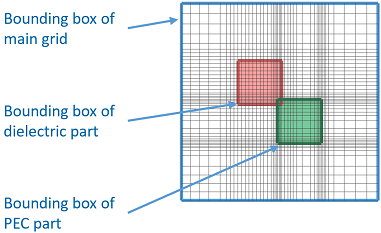

From the gridding algorithm's perspective, an XF project consists of a set of objects—such as the main grid, parts, components, waveguides, and manual grid regions—with overlapping bounding boxes, as well as clusters of fixed points. The main grid's bounding box is synonymous with the extent of the simulation space, and the bounding box of any other object is determined by its geometric size. Depending on the object type, local grid settings define how the grid is defined within its bounding box. A fixed point provides a location in space where a grid line should be placed.

Please log in to view this content.

Remcom customers and those interested in our products may access this content after logging in.